Global supply chain shifts due to regional conflicts

Global supply chain shifts due to regional conflicts lead to significant disruptions, requiring businesses to adopt innovative strategies, leverage technology, and prioritize sustainability to maintain resilience and competitiveness.

The global supply chain shifts due to regional conflicts have been reshaping commerce as we know it. With geopolitical tensions on the rise, it makes you wonder how these changes might affect everyday goods you rely on. Let’s dive into the nuances of this evolving landscape.

Understanding the impact of regional conflicts

Understanding the impact of regional conflicts on supply chains is crucial for businesses today. These conflicts can lead to disruptions, affecting various industries and the flow of goods. As tensions rise, companies must be aware of how these conflicts can ripple through their operations.

Key Factors in Regional Conflicts

Several factors contribute to the impact of regional conflicts on global supply chains. These include economic interests, political instability, and trade regulations. Each of these factors can create barriers to trade, influencing how products are sourced and delivered.

- Economic downturns may reduce demand for goods.

- Political instability can lead to unexpected closures of borders.

- Changes in trade regulations may increase costs and delays.

A notable example is the recent upheaval in Eastern Europe, which has caused major disruptions in the supply of critical resources. These events have pushed businesses to rethink their sourcing strategies and look for alternatives.

Strategies for Business Resilience

Adapting to these changes is essential for survival. Companies are increasingly focusing on resilience in their supply chains. This means identifying potential risks and developing strategies to mitigate them. Businesses are:

- Diversifying their supplier base to reduce dependency on a single region.

- Investing in technology to better predict and respond to disruptions.

- Enhancing logistics and transportation networks for flexibility.

By implementing these strategies, companies can navigate the complexities that arise from regional conflicts and maintain a steady flow of supply.

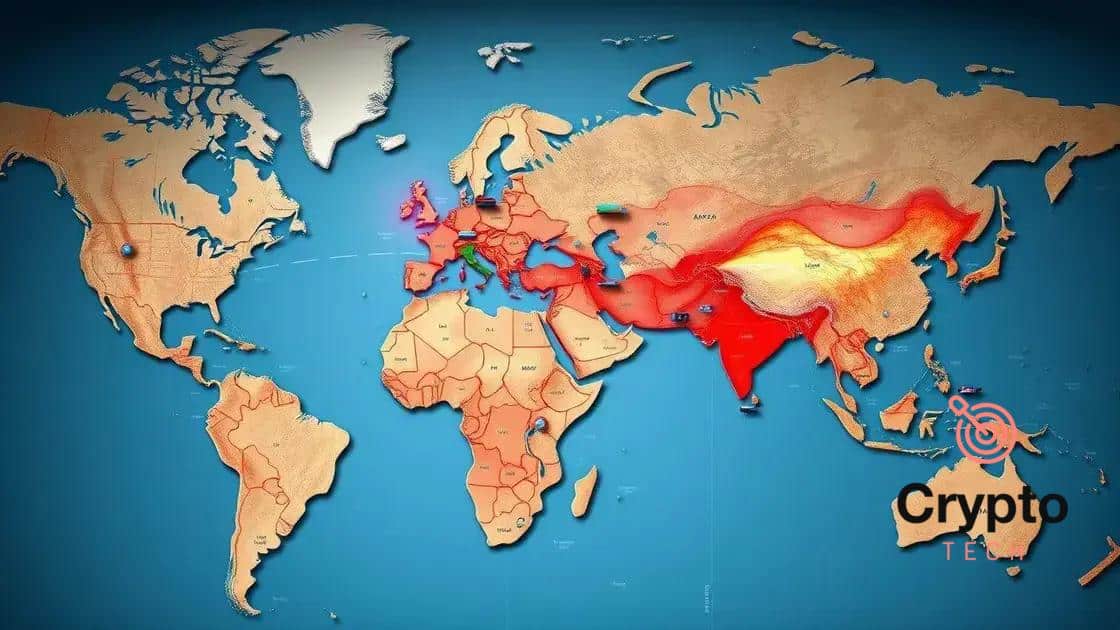

Key regions affected by supply chain changes

Key regions affected by supply chain changes highlight how global conflicts can disrupt trade. Understanding these areas is vital for businesses aiming to adapt to the evolving landscape.

Areas of Impact

Several regions around the world play critical roles in the supply chain. They include:

- Eastern Europe – Home to many conflict zones, this region has experienced significant disruptions in logistics, affecting the supply of raw materials.

- Asia-Pacific – This region is central to manufacturing. Political tensions can lead to delays and increased costs in shipping and production.

- Middle East – As a key player in oil supply, conflicts here can cause widespread shortages and price fluctuations impacting global markets.

These regions are interlinked, and changes in one can lead to ripple effects across the globe. The interconnectedness of the supply chain means that businesses must stay informed about regional conflicts.

Adapting to Regional Disruptions

Companies must proactively manage their supply chains to minimize risks associated with conflicts. Diversifying suppliers can help mitigate the impact of disruptions. By sourcing materials from multiple regions, a business can reduce its dependence on any single area. This approach not only enhances supply chain resilience but also offers flexibility in response to geopolitical changes.

Moreover, maintaining strong relationships with suppliers in stable regions can provide a buffer during crises. As conflicts arise, evaluating and adjusting sourcing strategies becomes essential for sustaining operations.

How businesses are adapting to disruptions

Businesses are facing numerous challenges due to supply chain disruptions caused by regional conflicts. Adaptation strategies have become essential for survival in this changing landscape.

Innovative Strategies for Adaptation

Companies are employing various innovative strategies to navigate disruptions. They are:

- Diversifying suppliers to reduce reliance on a single source. This approach helps protect against localized issues.

- Investing in technology to improve visibility across the supply chain. Tools like AI and data analytics provide real-time insights.

- Building flexibility into logistics systems to quickly shift routes or methods as needed.

These strategies reflect a shift toward more resilient operations, which are crucial when faced with unforeseen challenges.

Collaboration and Communication

Collaboration among stakeholders is another key strategy. Businesses are focusing on stronger relationships with suppliers, customers, and logistics partners. Enhanced communication ensures that everyone is on the same page, allowing quicker responses to disruptions. Building trust in these relationships allows for a better understanding of each partner’s capabilities and limitations.

Moreover, many companies are establishing contingency plans that outline specific actions to take during different types of disruptions. These plans help streamline decision-making and minimize downtime.

Emphasizing Sustainability

Interestingly, businesses are also turning to sustainability as a means of adaptation. Companies that integrate sustainability into their operations are often more agile and better prepared for disruptions. By utilizing sustainable practices, such as reducing waste and optimizing resource use, they not only support the environment but also create more efficient supply chains.

This focus on sustainability can enhance brand reputation and attract customers who value responsible practices, further solidifying a company’s position in the market.

The role of technology in supply chain resilience

The role of technology in supply chain resilience cannot be overstated. In today’s fast-paced environment, businesses must leverage digital tools to navigate disruptions effectively.

Enhancing Visibility with Technology

One major advantage of technology is the enhanced visibility it provides across the supply chain. With tools such as real-time tracking systems and data analytics, companies can monitor their supply chain at every step. This capability allows businesses to identify potential disruptions before they escalate.

- Real-time data from sensors and IoT devices helps companies make informed decisions quickly.

- Data analytics can predict trends, enabling proactive planning and risk management.

- Cloud-based platforms offer a centralized location for all supply chain data, improving collaboration among teams.

By utilizing these tools, companies become more agile and better prepared for unexpected changes.

Automation and Efficiency

Automation technologies also play a critical role in improving supply chain efficiency. Robotics and automated systems reduce human error and increase speed in processes such as inventory management and order fulfillment. For instance, warehouses can use automated guided vehicles (AGVs) to transport goods without human intervention. This not only speeds up operations but also reduces costs.

Moreover, automation allows businesses to reallocate human resources towards more strategic tasks, further enhancing productivity.

Cybersecurity Considerations

While technology offers numerous benefits, businesses must also prioritize cybersecurity. As reliance on digital tools increases, so does the risk of cyber threats. Implementing strong cybersecurity measures is crucial in protecting sensitive data and maintaining operational integrity.

By investing in cybersecurity solutions and training employees, organizations can build a secure and resilient supply chain that withstands both physical and digital disruptions.

Future trends in global supply chains

The future trends in global supply chains indicate significant changes driven by technology, sustainability, and evolving consumer demands. Businesses must stay updated to remain competitive in this dynamic environment.

Increased Automation

One major trend is the rise of automation in logistics and supply chain operations. Automated warehouses and robotic systems help streamline processes and reduce human error. This efficiency allows companies to respond more quickly to market needs.

- Robotics improves order fulfillment speed and accuracy.

- Automated systems reduce costs and enhance efficiency in inventory management.

- Adopting drones for delivery can further speed up logistics operations.

As automation technology continues to advance, its implementation will likely become standard in the industry.

Sustainability Initiatives

Another significant trend is the growing focus on sustainability within supply chains. Companies are increasingly aware of their environmental impact and are looking to implement greener practices. This includes using renewable energy sources, reducing waste, and optimizing transportation routes to lower carbon emissions.

Many businesses are also adopting circular economy principles. This approach encourages recycling materials and reusing products to minimize waste. As consumers become more environmentally conscious, companies that prioritize sustainability can improve their reputation and attract more customers.

Digital Transformation

Digital transformation is reshaping global supply chains as well. The integration of advanced technologies, such as blockchain and IoT, enhances transparency and traceability. Blockchain technology allows companies to track products from origin to delivery, ensuring authenticity and reducing fraud.

The Internet of Things (IoT) connects devices and systems, providing real-time data that can improve decision-making. By leveraging these technologies, businesses can enhance supply chain efficiency and responsiveness to changing market conditions.

FAQ – Questions About Global Supply Chain Shifts

How can technology improve supply chains?

Technology enhances supply chains by providing real-time data, automating processes, and improving visibility, which helps businesses respond quickly to disruptions.

What role does sustainability play in supply chains?

Sustainability is crucial as consumers increasingly prefer eco-friendly practices. Companies adopting sustainable practices can enhance their brand image and attract more customers.

What are some future trends in global supply chains?

Future trends include increased automation, the integration of advanced technologies like IoT and blockchain, and a stronger focus on sustainability.

How can businesses build resilience in their supply chains?

Businesses can build resilience by diversifying suppliers, investing in technology, and developing strong relationships with partners to deal with disruptions effectively.